Investigation of Drying Characteristics and Estimation of Mass Transfer Parameters of Sri Lankan Black Pepper Dried in a Batch Fluidized Bed Dryer.

##plugins.themes.academic_pro.article.main##

Abstract

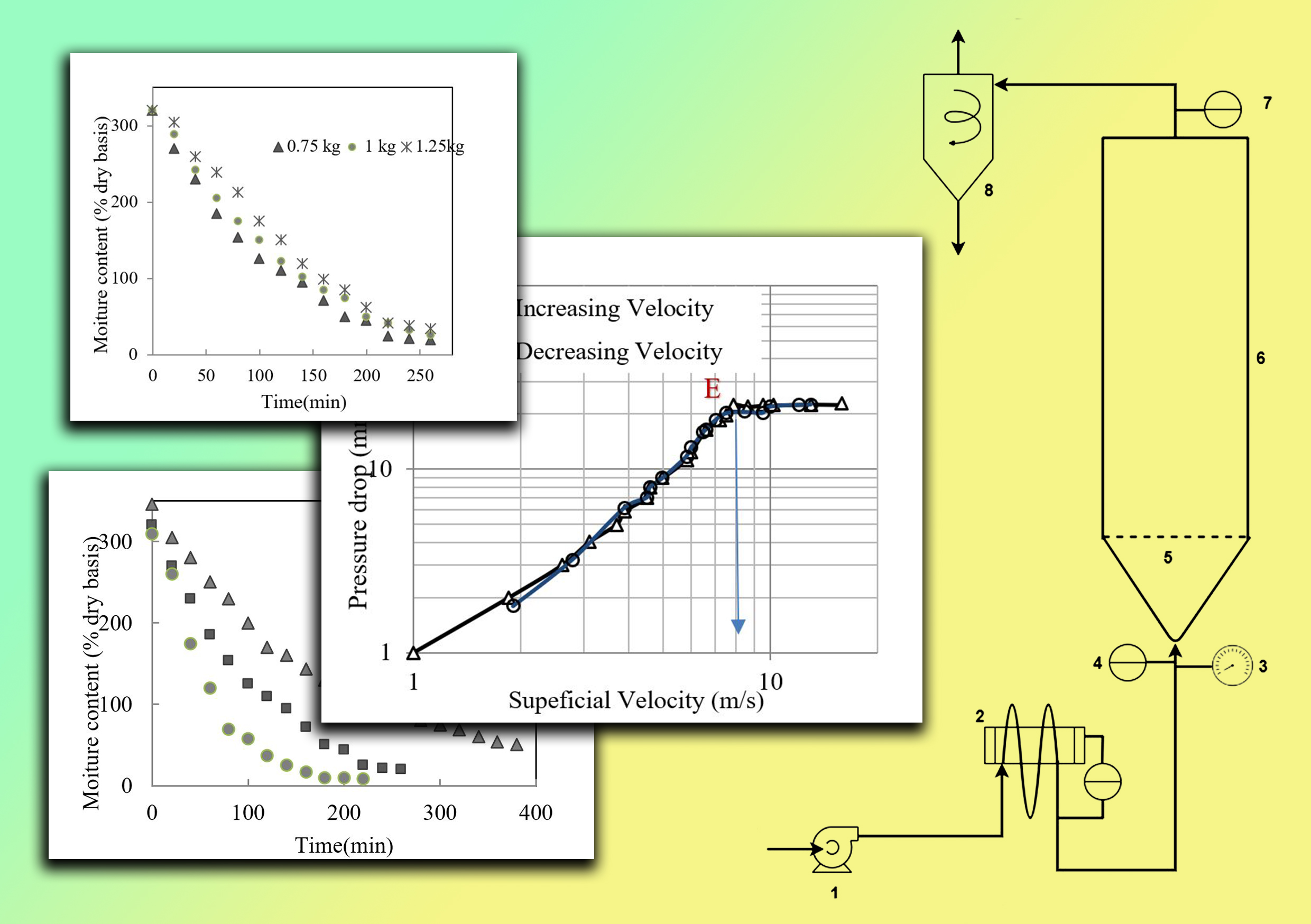

The drying of Sri Lankan black pepper was studied using a lab-scale batch fluidized bed dryer at three different temperatures of 55 °C, 65 ºC, and 75 ºC. Minimum fluidization velocities were determined for different bed weights. The effect of drying temperature and bed weight on the drying rate of black pepper in a fluidized bed was studied. Higher drying rates were observed at higher drying air temperatures and lower bed weights. Experimentally determined moisture ratios with time were fitted into twelve thin-layer drying models. Statistical indicators: Coefficient of determination (R2), Root mean square error (RMSE) and reduced chi-square values (c2) showed that the Midilli et. al model gives the best fit to the experimental values to describe the drying of black pepper in the fluidized bed. The absence of the constant drying rate period in drying curves shows the drying of black pepper lies totally in the falling rate period where the drying rate is controlled by moisture diffusion. Maximum drying rates observed were 1.7, 3.8, and 5.9 kg moisture/kg of dry material per minute at 55 ˚C, 65 ºC, and 75 ºC drying temperatures respectively. Results revealed drying rate constant and the effective moisture diffusivity values increase with the hot air temperature. Drying rate constants in the Midilli et. al model were 0.0055, 0.0109, and 0.0197 min-1 and the effective moisture diffusivity values were 1.071 × 10-10, 2.032 ×10-10, 2.844 × 10-10 m2/s for 55 ˚C, 65 ºC and 75 ºC of drying temperatures respectively. The activation energy for moisture diffusivity was 46.518 kJ/mol.

Keywords: Black pepper, Fluidization, Drying, Diffusivity, Mass transfer, Activation energy